Facilities

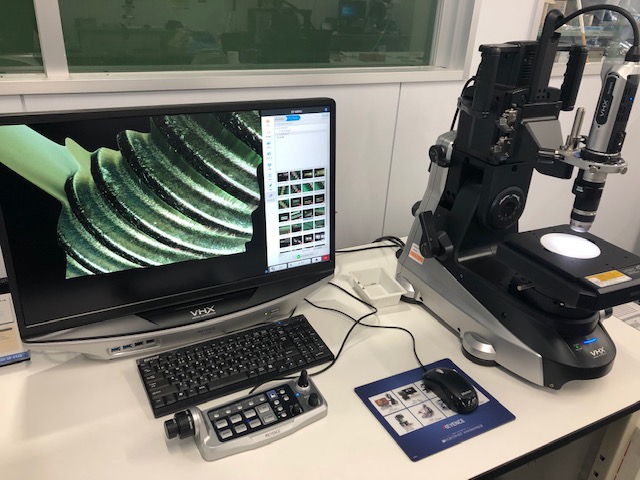

Introduction of a Digital Microscope

We introduce a new Digital Microscope, VHX-7000 manufactured by Keyence.

It offers ultra-fine resolution with 4K video CMOS. (Six times more resolution)

We use it to improve our surface inspections of lead screws required high accuracy.

Introduction of VR-5000, 3D shape analyzer

We introduced a one-shot 3D shape analyzer, VR-5000 by Keyence, and improve the inspection of our products to be quicker and more accurate.

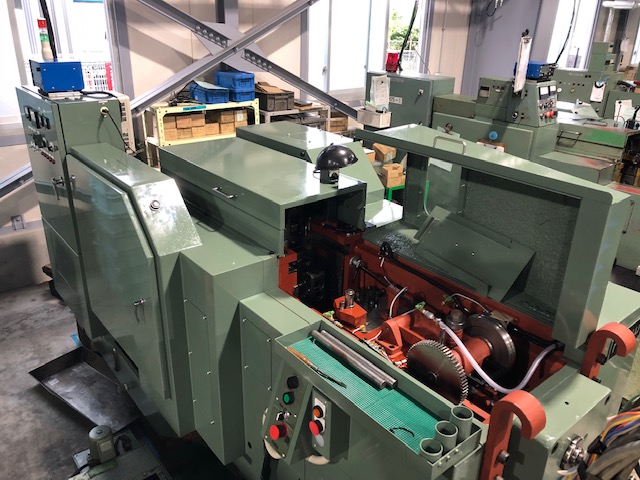

Overhauled Double Header, H-25

We overhauled the double header “H – 25″ for φ8 made by Nakashimada Engineering Works, used since 1989. It started operation again as it became new. Our company still has many processing machines of the same generation. In addition to switching to new machines, we will also carry out overhaul sequentially and strive to maintain high level of accuracy and productivity.

Installation of additional three rolling machines for precision screws.

We installed additional three rolling machines (rebuilt) for precision screws to correspond to our customers’ order increases and high-mix low-volume productions.

Those equip state-of-the-art sensors to avoid defects can be operated 24 hours a day by automatic fulling.

M8 rolling machine, THI-8R, overhauled

The 8R for thread rolling up to M8 is a machine that has been active in our company for nearly 30 years since 1989, but it is suitable for our company because of speed and compact compared with the existing 10R. Thus, we overhauled it now for 20 or 30 years later.